PRODUCTS: Choosing a Sensor

A range of models of LaserGauge® Sensors are available for specific applications or industries.

LaserGauge® sensors are available for portable, handheld, or assembly line use and take accurate measurements on opaque, transparent, and shiny materials.

What to consider when selecting a sensor

Following are the major considerations faced when selecting a LaserGauge® sensor:

- Feature(s) to be inspected

- Nominal value of the feature to be measured, and accuracy requirements (determines Field of View)

- Handheld or connected to a computer

- Material that will be measured – solid, non-shiny materials only (red laser) or solid materials, plus, shiny, translucent, and transparent (blue laser)

- Benefit you are looking to gain over your current inspection tools (speed and efficiency, data recording, precision, etc.)

- Budget and timeframe

Download How-To Guides

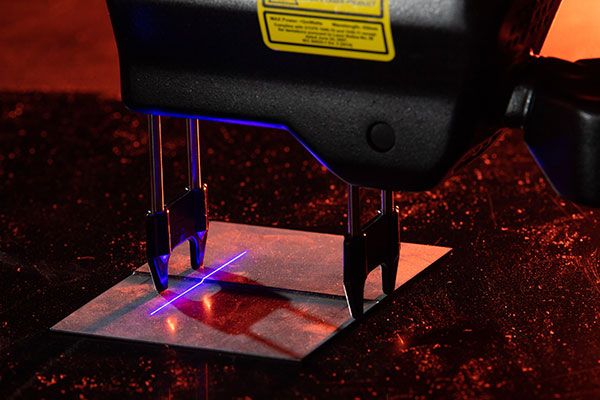

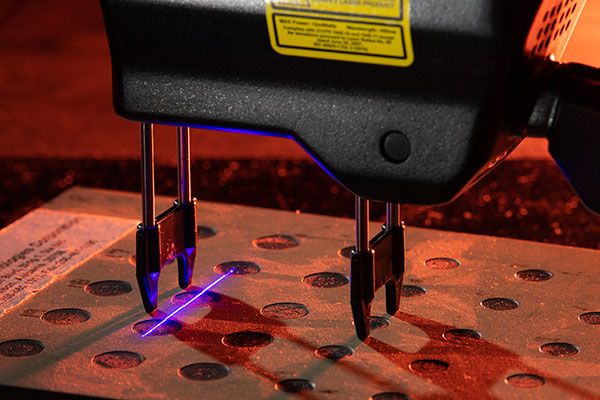

Choosing between Red or Blue Laser Technology

Selection of Red vs Blue laser technology comes down to a question of the surface material being measured. Red laser technology is used on solid surfaces, such as painted or unpainted non-shiny surfaces, and is less expensive. Blue laser technology works accurately on various surfaces including painted, unpainted, translucent, transparent, some plastic, composite, and shiny.

Choosing a LaserGauge® Sensor by Application

Scratches, Pitting, Corrosion, Surface Roughness

- Field of View: 0.5"

- Resolution: 0.0004"

- Choose this Sensor: USB

Edge Radius, Aerospace Step/Gap/Angle, Aircraft Fasteners, Welds

- Field of View: 1.2"

- Resolution: 0.0010"

- Choose this Sensor: DSP Single Stripe

Interior & Exterior Automotive Gap/Flush

- Field of View: 1.5”

- Resolution: 0.0012"

- Choose this Sensor: DSP Cross-Vector

Large Vehicle Gap/Flush, Welds

- Field of View: 1.9” (DSP Single Stripe) to 2.0” (USB)

- Resolution: 0.0015"

- Choose this Sensor: DSP Single Stripe or USB

Aircraft fasteners, countersinks, fill

- Field of View: 1.2" x 1.2” grid

- Resolution: 0.0015"

- Choose this Sensor Type: DSP 3D Cross-Hatch

Choosing a LaserGauge® Sensor by Model Features

DSP Sensor

- Main Features

- Stand-alone operation

- Portable, fast

- Single and Cross-Vector scanning

- Field of View

- 1.2" (30mm)

- 1.9" (48mm)

- 2.5" (63mm)

- Applications

- Gap/flush

- Step/gap/angle

- Radius

- Welds

- Fasteners/rivets

- Adhesive bead height

- Dents/gouges/tool marks

USB Sensor

- Main Features

- Very small, compact

- Most accurate

- USB Interface to PC

- Optional Controller

- Accurate to 0.0004”

- Field of View

- 0.5" (15mm)

- 1.0" (25mm)

- 2.0" (50mm)

- Applications

- Gap/flush

- Step/gap/angle

- Pitting/corrosion

- Scratches

- Laser welds

- Other welds

- Edge break/chamfer

- Fastener/Rivets

Leading Edge Sensor

- Main Features

- Inspect Leading Edge of blades, primarily in jet engines and other aerospace applications

- Accurate to 0.0005"

- Field of View

- 0.150" (3mm)

- 0.250" (6mm)

- Applications

- Turbine blades

- Compressor blades

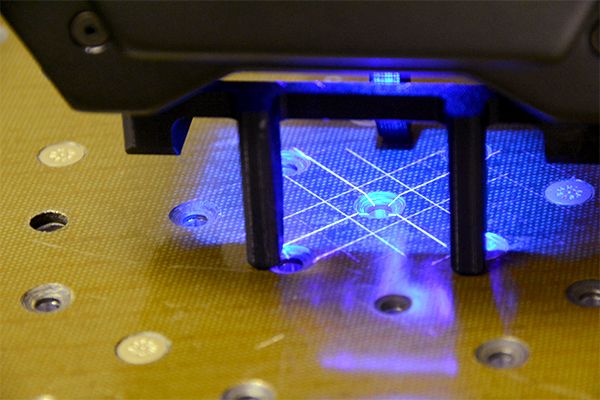

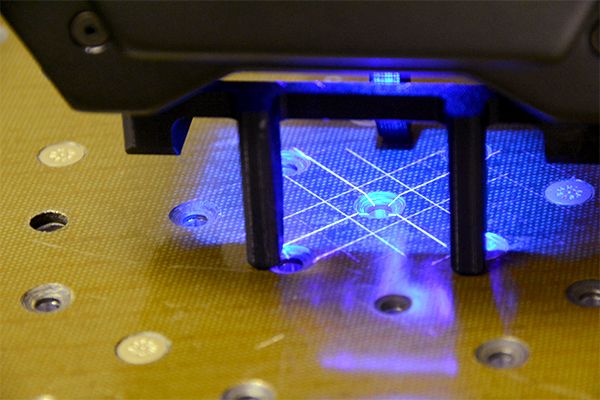

DSP 3D Sensor

- Main Features

- Stand-alone operation

- Portable, fast

- Specialized

- 3D Cross-Hatch scanning

- Field of View

- 1.2" x 1.2” grid region (30mm x 30.mm)

- 0.25" to 0.625" diameter range

- Applications

- Fasteners/rivets/pin depth

- Countersink alignment

- Dielectric fill height

LaserGauge® Automation System is available for assembly line use.

The LaserGauge® Automation System incorporates inspection routines, industrial network connection capabilities, collision avoidance, and an optional fitter’s station.

More than 40 accessories and replacement parts are available for LaserGauge® sensors.

Batteries, chargers, standoffs, check blocks, and more. Explore the range of accessories available for your LaserGauge® sensor.